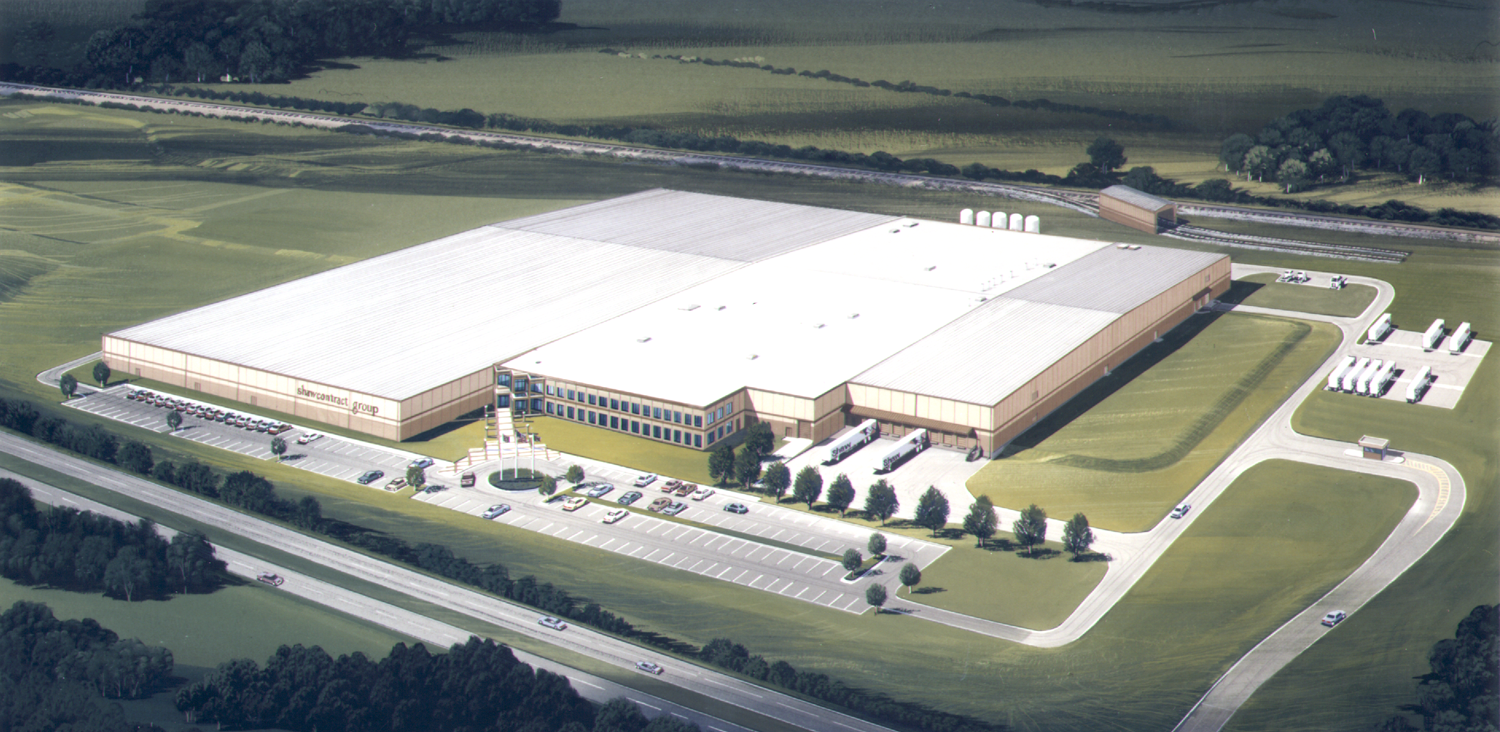

When Shaw Industries built Plant T1, located in Adairsville, Georgia they recognized the need

for a balanced air solution to keep their factory clean and their employees comfortable and happy. This 2.2 Million Sq.Ft. warehouse, the largest warehouse in the United States in 2015, would need six full air exchanges within an hour determined by ventilation codes.

Creating this full air exchange is important because it helps keep employees cool and comfortable increasing productivity. A clean warehouse is created by introducing fresh air, which helps maintain the overall building’s healthy by replacing stagnant, humid air; typical for the region.

S&P USA worked with Georgia Air to determine that HREB-C belt drive hooded roof exhaust fans and

HRSB hooded roof supply fans were needed to create a balanced airflow. HREB-C fans focus on exhausting the air that is contaminated from the machinery used within production. HRSB fans bring in the fresh air that helps the staff stay comfortable, and they provide positive pressure inside the warehouse to keep it clean.

Picking these models was essential to the project because it allowed the customer to have a model that looked similar and allowed it to be painted to match their roof, something that was important to them. Learn more in our full case study about the advantages of using HREB-C and HRSB exhaust and supply fans on your next warehouse project.

Why is Ventilation Important in a Warehouse?

1. It keeps employees cool by evaporating sweat and creating convection of body heat.

2. It keeps the warehouse cool.

3. It saves cost in heating and cooling that is not possible in a warehouse of this size.

Did you know that S&P offers Application Guides for some of your biggest projects? Discover our Warehouse Application Guide here.